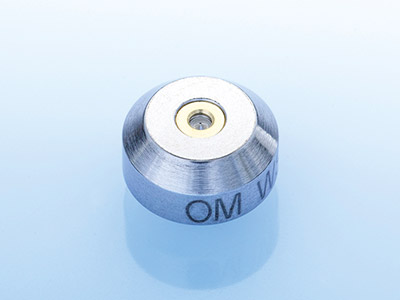

Razor-sharp – the perfect jet

Water is soft, but if we bundle the jet in a gemstone nozzle and add pressure, the extremely thin jet is transformed into a razor-sharp tool: ideal for precise cutting. We distinguish between pure water jet cutting and abrasive cutting. The benefits are obvious:

- Cold cutting

- No warpage due to thermal stress

- No burr formation and no burn marks